What Are You Looking For?

Vision, Mission & Core Values

Guided by these principles, we are committed to delivering high-quality, reliable solutions that meet the evolving needs of global industries.

Global Manufacturing Bases

Quality & Certifications

R&D Capability & Patents

Innovation is at the heart of our growth. We boast an independent R&D team and advanced enterprise technology centers, dedicated to material innovation, process optimization, and customized solution development. Our technical strength is validated by 5 national invention patents and 28 utility model patents, covering core areas such as amorphous/nanocrystalline material formulation, magnetic core manufacturing, and power device integration.

We continuously invest in R&D to stay ahead of industry trends, enabling us to provide custom power components and patented electronic components for demanding applications. Our focus on R&D also allows us to replace imported products (e.g., from Hitachi and VAC) with high-performance, cost-effective alternatives.

Core Products

We offer a full range of high-performance products, categorized into four key lines, widely used in home appliances, power equipment, consumer electronics, photovoltaic (PV) systems, new energy vehicles (NEV), and wind-solar storage.

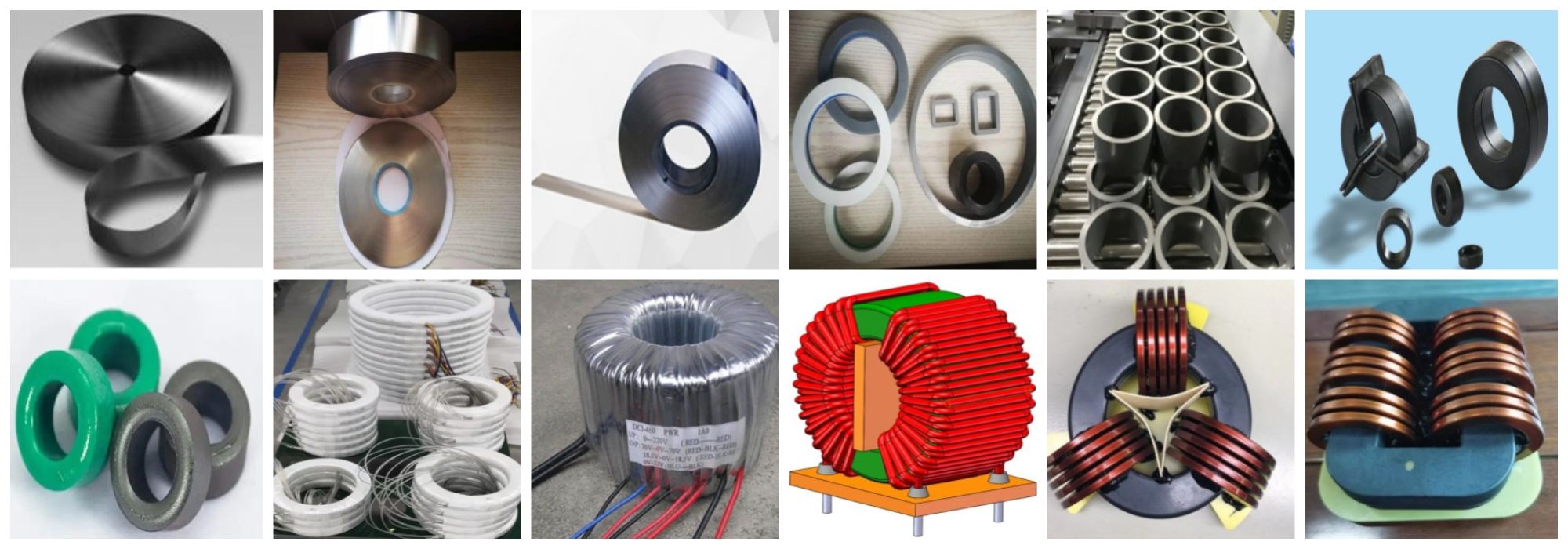

1. Magnetic Materials & Components

Amorphous Ribbons:

Gravity Ribbon (1k107): Features ultra-high permeability (initial permeability μi up to 200,000; maximum permeability μm up to 700,000) and high saturation magnetic flux density (Bs = 1.25 T), with low core loss, making it ideal for precision current transformers and power transformers.

Pressure Ribbon (1k107B): Produced via constant pressure technology, with thin thickness (12μm~16μm), high density, and excellent consistency—widely used in high-frequency common-mode inductors, high-power transformers, and wireless charging systems.

Nanocrystalline Ribbons:

FN Series Constant Permeability Ribbons (FN035-200): Offers high permeability linearity (3500~20000) and strong DC bias resistance, replacing imported equivalents for applications like PV PCS converters and automotive EMI filters.

Magnetic Cores:

Nanocrystalline Magnetic Cores: Wound from 1K107B material, featuring high saturation magnetic flux density, high permeability, and cost advantages over permalloy, it is widely used in transformers, inductors, and communication devices.

Ferrite Magnetic Cores: Made of nickel-zinc or manganese-zinc ferrite, with high permeability and low magnetic resistance—suitable for EMC and signal processing.

Silicon Steel Power Cores: Wound from oriented silicon steel with epoxy potting for stable performance in power current transformers.

2. Power Components

Current Transformers: Secondary Windings and Molded/Assembled Current Transformers (up to 1100kV) convert large currents to small ones for precise measurement and relay protection, applied in transformers, (H)GIS switchgear, and power grids.

Toroidal Transformers: Standard, economic, and isolation (industrial/medical) types—used in computers, medical equipment, audio devices, and inverter power supplies.

3. Electronic Components

Common Mode Inductors:

Low-power Wound Type: Filters common-mode electromagnetic interference (EMI) for switching power supplies, home appliances, and automotive DC/DC modules.

Medium/Higher-power Flat Wire Vertical Wound Type: Symmetrically wound on closed cores (120° spacing for medium-power; 4/6/8 coils for high-power) — ideal for PV inverters, wind-solar storage systems, and NEV converters.

4. High-Voltage Isolating Switches

Developed by Anhui Hangyou Intelligent Equipment Co., Ltd., our main knives and ground knives for high-voltage isolation switches are designed for load-free switching and equipment isolation in power plants and substations—supporting safe operation of high-voltage power transmission systems.

As an amorphous busbar manufacturer and high-voltage isolating switch supplier, our products are engineered to deliver efficiency, durability, and cost-effectiveness.

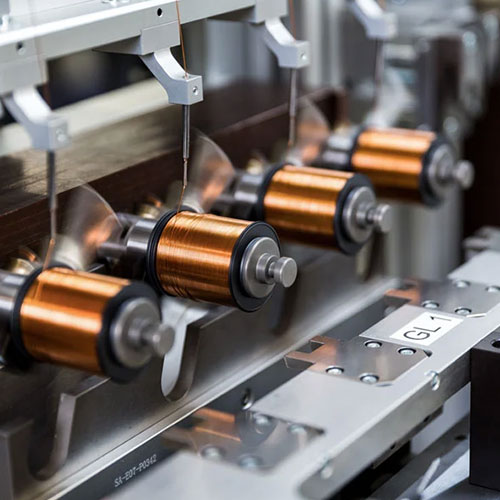

Smart Manufacturing & Capacity Planning

To support long-term growth, we are continuously upgrading our manufacturing capabilities with smart technologies:

Software: Fully implemented ERP system to optimize management efficiency, reduce operational costs, and enhance process precision.

Hardware: Under construction of AGV intelligent logistics system for unmanned material handling; standardized clean workshops to ensure product quality and employee health.

Capacity Expansion: We are scaling up production to meet global demand, with the following targets:

Application Industries & Trusted Partners

Our products are widely adopted across five core industries: home appliances, power equipment, consumer electronics, photovoltaic systems, and new energy vehicles. We maintain long-term cooperation with global industry leaders, including ABB, Hitachi Energy, Midea, Haier, SKYWORTH, TCL, Foton Motor, Megmeet, and Gree—building trust through consistent quality and reliable service.

Join Hands with Hangyou

With our global manufacturing network, advanced R&D capabilities, strict quality control, and customer-centric approach, Hangyou Electric is dedicated to becoming your reliable partner for magnetic materials, power components, and customized solutions. Whether you need OEM, ODM, or tailored products for specific applications, we have the expertise and resources to deliver excellence.

Visit our official website: www.amorphousbus.com

We welcome global customers to contact us and explore win-win cooperation!

leave a message